Green Sim Racing

How Rock Solid Rigs help lower your Carbon Footprint

Aluminum is one of the most commonly used materials in sim rig construction due to its strength and durability. However, its production and manufacturing processes have a significant environmental impact. The process of extracting bauxite, the raw material for aluminum, involves strip mining large areas of land, which can result in deforestation and habitat destruction. The mining process also consumes a vast amount of energy and water and produces toxic waste, which can contaminate nearby ecosystems and water sources.

Once the bauxite is extracted, it is refined into alumina, which is then smelted into aluminum using vast amounts of energy in the form of electricity. The production of aluminum requires significant amounts of fossil fuels, resulting in greenhouse gas emissions and contributing to climate change. Additionally, aluminum production is a water-intensive process, and the runoff from aluminum production plants can pollute nearby water sources.

Shipping aluminum across the world for manufacturing and distribution also adds to the environmental impact. The transportation sector is a significant contributor to greenhouse gas emissions, and the long distances traveled by aluminum parts contribute to this impact.

On the other hand, the use of wood in sim rig construction can provide a more sustainable alternative. Wood is a renewable resource, and sourcing wood locally reduces the environmental impact of long-distance transportation. Using wood in sim rig construction also requires less energy and produces fewer greenhouse gas emissions than aluminum production. The use of wood can also help reduce deforestation when sourced from responsibly managed forests.

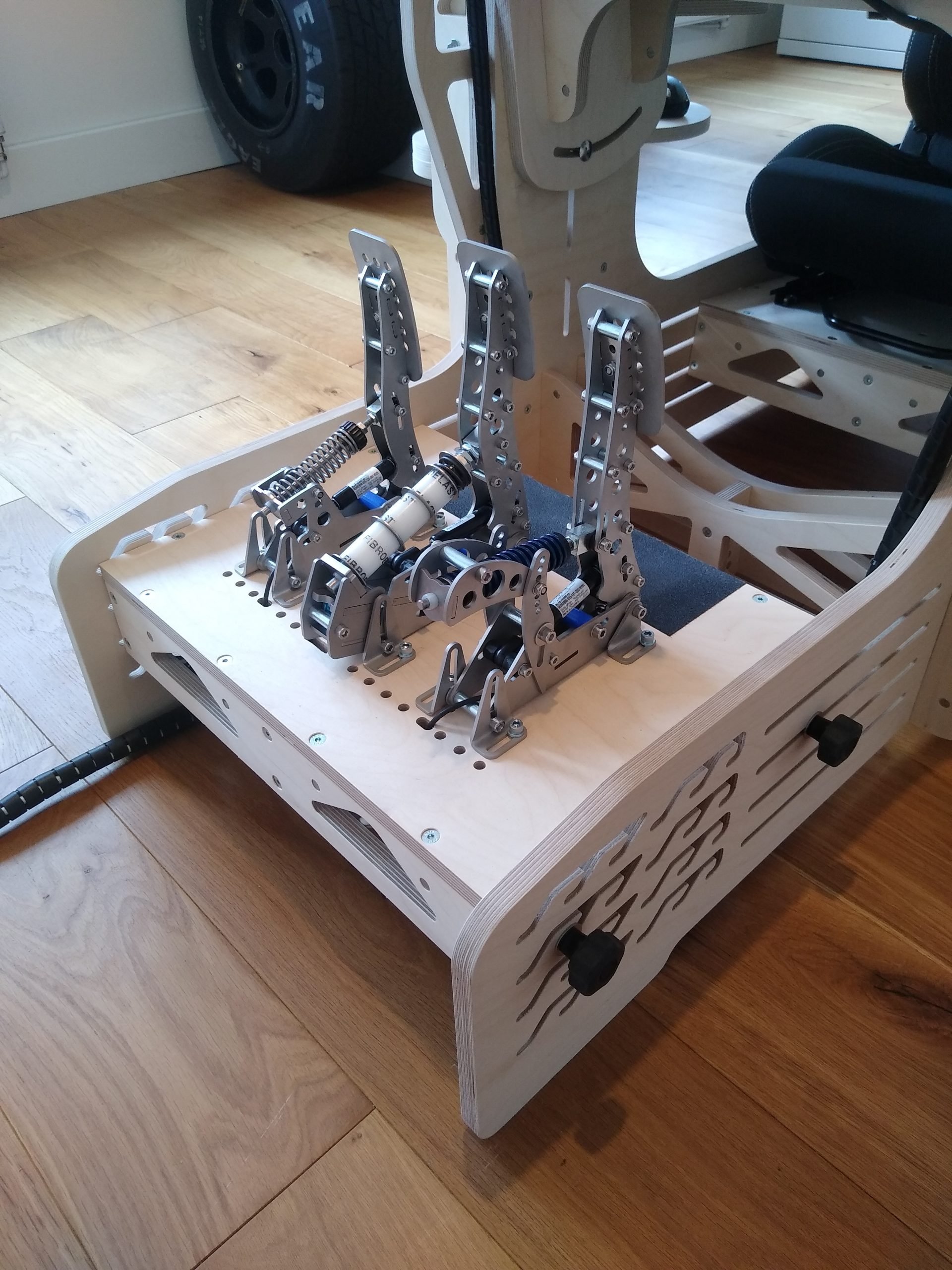

Rock Solid Rigs is a UK-based company that offers top-tier simulator chassis for racing and flight simulators. Designed by Formula One composite engineer, Mark Foster, the RSR-21 Simulator Cockpit is the flagship product of the company. It is a wooden simulator cockpit that meets or exceeds the performance of the highest-grade sim chassis on the market, optimized for maximum performance for drivers and pilots without gimmicks or compromised design.

The RSR-21 is the original professional Wooden Sim Racing Cockpit, designed to be one of the stiffest cockpits on the market due to its direct load paths and substantial sectional stiffness. The exceptional stiffness of the cockpit also allows screens to be mounted directly to it without vibration issues. Inspired by aircraft bulkhead design, the load paths are optimized using specialist software to provide greater system stiffness under steering and braking than most steel or aluminum cockpits, making you faster.

The structure of the cockpit is designed to be configured as a race or flight simulator without compromise. The exceptional stiffness allows screens to be mounted directly to the cockpit without vibration issues. Pre-drilled for Fanatec, Thrustmaster & Logitech hardware (fixings included), it can fit any seat or control system in any orientation with ease by drilling mounting holes into the heavy-duty 18mm thick plywood mounts. Monitor mounts are compatible with 50mm, 75mm & 100mm VESA patterns (fixings included).

The RSR-21 cockpit is made from UK-sourced Baltic Birch plywood, which is a renewable material that enables the cockpit geometry to be optimized for exceptional stiffness, utilizing ribs, spars, and triangulation throughout. The plywood and packaging are sourced from FSC-approved manufacturers, guaranteeing that the products do not contribute to deforestation and are considered renewable.

The adjustment ranges of the RSR-21 cockpit allow accurate driving/piloting position relative to controls and monitors for all driver sizes as well as vehicle types. The seat mount has a 20cm forward/back, 12cm vertical, 32° tilt adjustment range, while the pedal mount has a 20cm forward/back, 12cm vertical, 52° tilt adjustment range. The steering mount has a 21cm vertical, 50° tilt adjustment range. The cockpit stiffness remains consistent throughout adjustment ranges, and no tools are required.

Let's play devil's advocate. We love physical motorsport as much as any other fan but we cannot ignore costs.

Motorsport is an activity that requires a lot of practice and track-time to master. However, the cost and accessibility of track time can be a significant barrier for many enthusiasts. Fortunately, with the rise of motorsport simulators, there is now a more accessible and cost-effective way to improve racing skills and race craft.

One of the most significant advantages of simulators is the ability to practice and improve skills in any weather and at any time of the year. For example, on a cold, wet, and windy winter night in January, a driver can still practice and improve their lap times and race craft on a simulator. This flexibility can be especially beneficial for those who live in areas where inclement weather limits the availability of track time.

Simulators also provide the opportunity to race against thousands of other drivers from around the world. Online racing communities have emerged, allowing drivers to compete in virtual races against other enthusiasts. This not only provides a more diverse and competitive racing experience but also allows drivers to learn from others and develop their skills.

Moreover, simulators offer a range of tools and options to help drivers improve their lap times and race craft. For example, simulators allow drivers to change weather conditions, track layouts, and race times, providing a level of customization that is not possible in real-world racing. This allows drivers to practice and improve specific aspects of their driving, such as braking points or cornering speeds.

Additionally, simulators can help drivers develop muscle memory and reaction times that are transferable to real-world racing. As mentioned earlier, the design of simulators like the RSR-21 cockpit is based on the understanding that the stiffer and more accurately positioned the controls relative to the driver, the faster the lap time. This makes the driver's muscle memory and reactions learned in the simulator more transferable to the real car.

Overall, simulators offer a cost-effective and accessible alternative to track time for those looking to improve their racing skills and race craft. With the ability to practice and race at any time of the year and against thousands of other drivers from around the world, simulators provide a unique and valuable training tool for motorsport enthusiasts.

Let's dive into more detail on the environmental impact of running a track day or race car. As we mentioned earlier, the costs of running a track day car or race car can quickly add up, making it an expensive hobby. But it's not just the financial cost that we need to consider. The environmental impact of motorsport is significant, with the production, transportation, and disposal of race cars, parts, and equipment contributing to climate change.

Let's start with the production of race cars. Motorsport is an inherently resource-intensive industry, with race cars being produced from a wide range of materials including carbon fiber, aluminum, and steel. The production of these materials has a significant environmental impact, particularly in terms of energy consumption and greenhouse gas emissions. For example, the production of carbon fiber, a commonly used material in race car construction, requires significant amounts of energy and releases carbon dioxide (CO2) into the atmosphere.

In addition to the production of race cars, there is also the transportation of race cars, parts, and equipment to consider. Motorsport events are held all over the world, and getting race cars and equipment to these events often involves long-distance transportation, which contributes to greenhouse gas emissions. Furthermore, the disposal of race cars and parts at the end of their life cycle can also have a significant environmental impact.

So, what can be done to reduce the environmental impact of motorsport? One solution is to use sustainable materials in the construction of race cars and parts. For example, using wood in sim rig construction can provide a more sustainable alternative to aluminum, which is commonly used in sim rig construction due to its strength and durability. Wood is a renewable resource, and sourcing wood locally reduces the environmental impact of long-distance transportation. Using wood in sim rig construction also requires less energy and produces fewer greenhouse gas emissions than aluminum production.

Another solution is to reduce the number of motorsport events and promote more sustainable modes of transportation. For example, encouraging the use of public transportation to get to motorsport events can help reduce greenhouse gas emissions from transportation. Furthermore, the development of electric race cars and the use of renewable energy sources to power motorsport events can help reduce the environmental impact of motorsport.

In addition to these solutions, there are also ways to reduce the environmental impact of the track day and race car events. For example, using environmentally friendly fuels and lubricants can help reduce greenhouse gas emissions. Additionally, the implementation of environmentally sustainable practices, such as recycling and waste reduction, can help reduce the environmental impact of motorsport events.

The environmental impact of running a track day or race car is significant. The production, transportation, and disposal of race cars, parts, and equipment all contribute to greenhouse gas emissions and climate change. However, there are solutions available to reduce the environmental impact of motorsport. Using sustainable materials in the construction of race cars and parts, promoting sustainable modes of transportation, and implementing environmentally sustainable practices at motorsport events are all steps in the right direction. By working together, we can reduce the environmental impact of motorsport and ensure that it remains a sustainable and enjoyable hobby for generations to come.